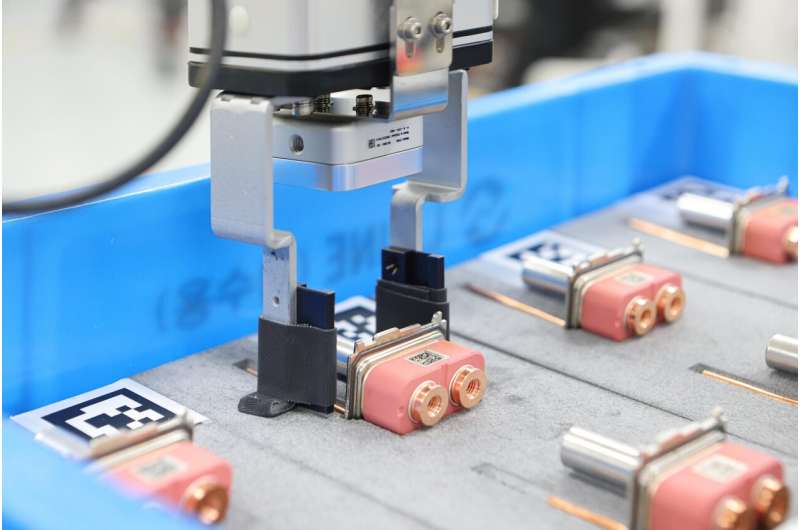

Testbed for manufacturing processes using robots: Image of research results. Credit: Korea Institute of Mechanical Materials (KIMM)

We have developed the world’s first AI (artificial intelligence) technology for robotics, which makes it easy to introduce robots into manufacturing processes. The technology we developed can be used in a variety of processes, including the manufacturing, assembly and production of automobiles and machine parts, and is expected to contribute to improving the working environment at manufacturing sites in the future.

A research team led by Kim Chang-hyun, director of the AI Machinery Research Department at the Korea Institute of Mechanical Engineering (KIMM), has successfully developed AI technology for robot work that can be easily applied to manufacturing processes.

This new technology is currently being applied to the manufacturing processes of electronic component manufacturers. The research team plans to gradually expand the range of manufacturers to which the newly developed technology can be applied.

The AI technology developed by KIMM for robot work at manufacturing sites is based on large language models (LLM) and virtual environments. It is a technology that understands the user’s commands and automatically generates and executes the commands for the tasks that the robot should perform.

This technology makes it possible to automatically generate work procedures and actions using voice and text, and through advance learning in virtual space, it is possible to select the optimal work points for the site, as well as shorten work processes, automatically detect objects, avoid collisions, etc. It’s also helpful.

On-site application testing of robotic manufacturing processes: Research results image. Courtesy of Korea Institute for Machinery Research (KIMM).

Until now, when working with robots at manufacturing sites, it was necessary to modify the site itself to suit the robot, rather than modifying it to suit the work environment or target object, and the scope of work that robots could perform was limited. Ta. In addition, it is necessary to develop technology that integrates various technologies related to work, such as movement technology and recognition technology, but only a portion of such technology has been developed yet.

Recently, AI technologies such as LLM and robots have been combined and used for a variety of tasks. However, these technologies have been tested only in laboratory environments, not in real-world settings, making it difficult to apply them to real-world settings.

With this newly developed technology, it is possible to specify the tasks to be performed by a robot, and by conducting prior learning in a virtual space, the robot can easily perform the tasks with minimal modification on-site. On-site demonstration experiments are currently being conducted, and it is expected that in the future the technology will be able to effectively respond to a variety of situations that may occur on manufacturing sites.

AI robot holding electronic components: Image of research results. Courtesy of Korea Institute for Machinery (KIMM)

Kim Chang-hyun, head of KIMM’s AI Mechanical Department, said, “This is the first time in the world that we have combined AI technology and robot technology, developed intelligence specialized for robot work, and applied it to an actual manufacturing site.” .

“The technology is currently being tested in the production process of an electric vehicle (EV) parts manufacturer and its scope of application will expand gradually,” he added.

Provided by the National Science and Engineering Research Council

Quote: Team developing AI technology for robotic work applicable to manufacturing processes (January 16, 2024) Retrieved May 23, 2024 https://techxplore.com/news/2024-01-team-ai-technology-robot.html

This document is subject to copyright. It may not be reproduced without written permission, except for fair dealing for the purposes of personal study or research. The content is provided for informational purposes only.